Relying on the innovation system of National Enterprise Technology Center, we increase our investments in product research and development, and make constant efforts to accomplish independent product development, industry-university-research cooperation, cooperative business operation, and high-tech talents attraction. These enable us to greatly improve our original innovation, integrated innovation, and re-innovation capacities, and make us a leader in environmental protection and energy saving fields. We have been successfully created into a national brand with core competitiveness and sustainable development capacity.

1. Independent innovation capability

Refrigeration compressor core technologies

During our research for refrigeration screw compressors, we innovatively utilized a sensor to record the p-V diagram of compressor rotor.

The achievement has been published on International Journal of Refrigeration which represents the highest level of refrigeration technologies. Another three theses has been published on SCI and EI.

By now, we have earned 7 independent intellectual property rights for our refrigeration screw compressors. According to the testing results by national authorities, our refrigeration compressors offer 6.7% increase in refrigerating capacity and 5-10dB reduction in noise. The comprehensive performance has reached international advanced level.

System Integration

Not only providing reliable refrigeration equipment, we also supply complete system integration techniques and extended services. Adhering to the principle of "internationalized technology, automatic system, customer oriented service", we offer a complete range of services from project programming, through technical consultation, engineering design, equipment matching, installation and testing, equipment maintenance, technical training, follow-up services for products, to final system improvement and upgrading. We can also meet clients' individual demands.

Energy saving and environmental protection

To fulfill our social responsibilities, we act actively to promote the utilization of low carbon, energy conservation, and environmental friendly technologies. To illustrate, we have innovatively applied new energy technologies such as water source, ground source and sewage source heat pumps, and use natural refrigerants such as CO2, propylene, propane, dimethyl ether, etc. in our refrigeration systems. CO2 refrigerant is safe, eco friendly, and energy saving, and we were the earliest manufacturer in China utilizing CO2 refrigeration system.

Our demonstration project of "utilizing NH3/CO2 cascade system instead of conventional R22 for refrigeration" has been approved as a Global HCFCs Replacement Demonstration Project by Montreal Protocol Multilateral Fund, United Nations Development Programme, and Ministry of Environmental Protection of the People's Republic of China. Presently, our CO2 refrigerating system has entered into wide application.

2. Innovations on Industry-University-Research Cooperation

On the basis of independent research and development, we enhanced our innovation on industry-university-research cooperation. In China, we established technical cooperation with over 10 universities, including Tsinghua University and Xi'an Jiaotong University, as well as scientific research institutes such as Technical Institute of Physics and Chemistry, CAS and Hefei General Machinery Research Institute. Additionally, we also have technical exchange and cooperation with international renowned corporations such as Ebara Corporation, Mayekawa Manufacturing Company, and Toyo Engineering Works in Japan, Danfoss in Danmark, and CABERO in Germany. Through national and international cooperation, we have successfully quickened our step in the technical development of our key products, as well as our research on forward-looking technologies.

We have created a new style of industry-university-research cooperation, that is, establishing strategic alliances for industrial technology innovation. By now, we have established strategic alliances with concerned units for the innovation on national agricultural products storage, transportation and fresh-keeping technologies, national fruits and vegetables processing technologies, as well as Shandong province agricultural products cold-chain logistics technologies.

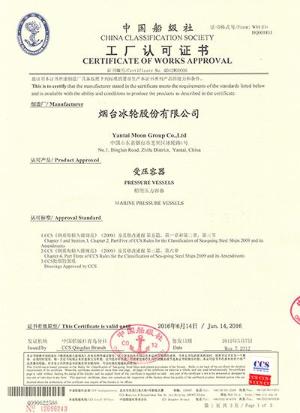

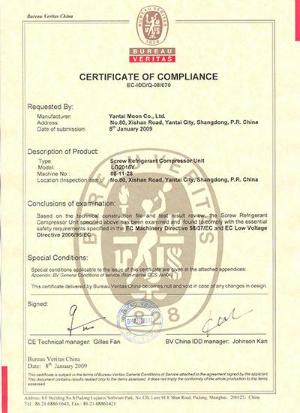

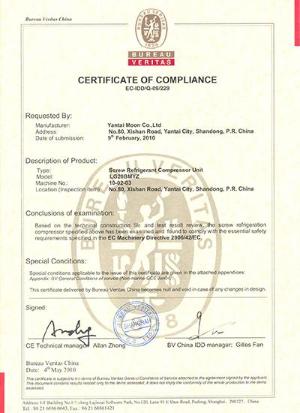

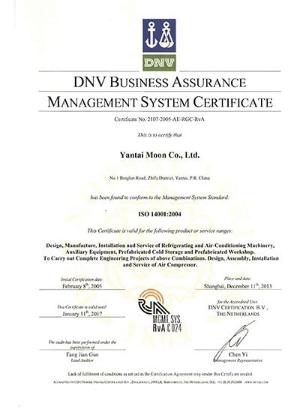

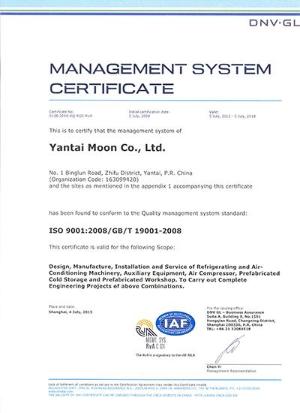

We have a complete quality assurance system, and we were the earliest refrigeration equipment manufacturer who have earned the ISO9001 quality management system certificate by DNV, ASME U-Stamp certification for pressure vessels, as well as ISO1400 environmental management system certificate by DNV. Additionally, we are outfitted with a compressor performance testing system which is built according to international universal technology standards and comes with the broadest testing range and the highest testing accuracy in China, domestic leading air end assembly lines, as well as world leading facilities for the production and testing of screw compressor rotors, housing, and other compressor key parts. Due to these, our range of refrigeration equipment offers incomparable quality in Chinese market.

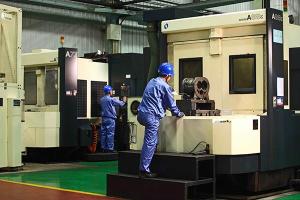

We are empowered by a complete range of performance production facilities, including:

1. CNC machining centers from America and Germany

2. MMC flexible manufacturing system from Makino in Japan

3. TG350E CNC rotor grinding machines from HOLROYD in UK, H35RL CNC rotor grinding machines from Klingelnberg in Germany, and CNC rotor grinding machines from Kapp in Germany

4. Precision CNC machine tools from Jones&shipman in UK, AMADA and Okuma in Japan

5. XCEL122010 coordinate measuring machines from BROWSE&SHARP in America

As the largest commercial and industrial refrigeration system solutions provider, we have the capacity to work with world leading suppliers, and also to work with Chinese leading suppliers so as to help save production cost. On the basis of system integration technologies and through our worldwide marketing and service network, we provide our clients with optimized refrigeration solutions to meet their specific demands. We also supply one-stop service to help save clients' time.